Tips for winter maintenance of natural gas vehicles

Precautions for using natural gas vehicles in winter

1. When refueling, it is essential to ensure that the gas filling port is clean to prevent water and contaminants from entering the cylinder and causing pipeline blockage.

2. The engine coolant must be antifreeze produced by a reputable manufacturer, and water must not be used. Furthermore, the antifreeze level must not fall below the minimum mark on the radiator, to prevent poor vaporization in the water bath carburetor due to frozen water pipes at low temperatures.

3. When ice forms in pipelines or valves, clean and oil-free warm water or hot nitrogen should be used to thaw them before operation. Do not use hammers or other objects to knock.

4. The filter element must be cleaned or replaced in a timely manner to prevent the pipeline from being blocked due to excessive dirt on the filter element.

Before parking the vehicle, it is necessary to run it at idle speed for 3 minutes. After the water temperature stabilizes, turn off the power and park the vehicle.

6. When parking the vehicle overnight, please close the pressure boost valve, discharge valve, and vent valve, and start the vehicle until it automatically shuts down to avoid ice blockage of residual gas in the pipeline due to low temperatures at night.

7. The booster coil must not be frozen. If there is any ice or excessive dirt, please clean it promptly to ensure smooth boosting.

8. Please run the vehicle at idle speed for 3 minutes when starting, and only operate the vehicle again when the water temperature reaches 40 degrees.

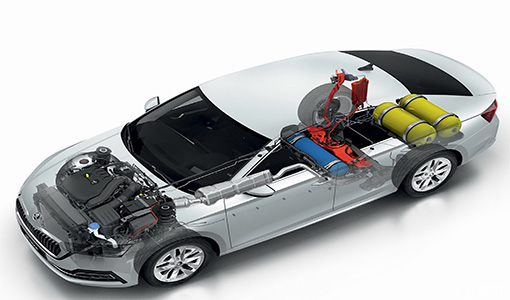

CNG natural gas vehicles store natural gas in compressed form in gas cylinders, so it is important to note the following during winter:

1.Before refueling, please confirm whether the gas contains water. To avoid ice blockage in the pipeline, please refuel with compressed natural gas that has undergone dehydration treatment.

2. When refueling, it is necessary to ensure that the gas filling port is clean to prevent water and dirt from entering the cylinder and causing pipeline blockage.

3. Freezing is not allowed on CNG pipelines, valves, solenoid valves, high-pressure fine filters, and pressure reducers. If it occurs, please clean it up promptly. 4. The high-pressure fine filter element must be cleaned or replaced in a timely manner to avoid poor gas supply caused by excessive dirt or ice blockage.

4. The engine coolant must be antifreeze from a reputable manufacturer and must not be water. Additionally, the antifreeze level should not fall below the minimum mark on the radiator, to prevent the pressure reducer from freezing due to a lack of antifreeze.

5.Before parking the vehicle, it is necessary to run it at idle speed for 3 minutes. After the water temperature stabilizes, turn off the power and park the vehicle.

6. When parking overnight, please close all cylinder ball valves and start the vehicle until it automatically shuts down to prevent residual gas and water in the pipeline from freezing at low temperatures at night, causing ice blockage.

7. Please run the vehicle at idle speed for 3 minutes when starting, and then operate the vehicle again when the water temperature reaches 40 degrees.

Troubleshooting methods for difficult starting of natural gas vehicles in winter

I. Ignition system malfunction

Due to the higher ignition point of natural gas compared to gasoline, the requirements for the working performance of components such as the ignition coil, ignition timing, mixture ratio, and starter initial speed are significantly higher when starting with natural gas at low temperatures compared to starting with gasoline. Therefore, it is necessary to regularly check and adjust the working performance of these components.

1. Insufficient ignition energy. Pull out the distributor main cylinder wire and test the high-voltage sparking performance. A strong blue spark should appear, and the air breakdown gap for high-voltage sparking should be above 0.8 cm. Since natural gas has a high ignition point (above 650 degrees), which is 223 degrees higher than gasoline, and the combustion rate of the mixture is slower than gasoline, the ignition intensity is required to be higher than that of gasoline.

2. Inaccurate ignition advance angle: Due to the slower flame propagation speed of natural gas compared to gasoline, the ignition advance angle should be 3-7 degrees earlier than when using gasoline to ensure the power performance of the engine.

3. Breakdown or cracking of high-voltage wires, distributor covers, or distributor heads may cause leakage, resulting in individual cylinders not working. Replacement or adjustment should be made depending on the situation.

4. The spark plug is not sparking properly (due to excessive carbon buildup and severe electrode erosion). The spark plug electrode gap should be 0.6-0.8 millimeters (equivalent to the thickness of a steel saw blade), and it should not be too large or too small.

5. The battery voltage is too low, the battery is in a weak state, the ignition energy is insufficient, or the battery terminal is corroded or loose, and the battery cable is aged and leaking.

6. Distributor fault: Internal transistor components of the control module (amplifier) are damaged, the magnetic induction coil is open-circuited or short-circuited, the distributor shaft is broken or loose. If it cannot be repaired, a new control module or distributor should be replaced; the magnetic induction gap of the distributor is not properly adjusted (the normal gap is generally 0.7 millimeters).

7. If the motor speed is too low (the engine speed is less than 60 rpm), it may be due to loose or damaged motor terminals that need to be tightened in time. If the internal rotor, coil, or suction switch of the motor is damaged, the motor needs to be repaired.

II. Gas device malfunction

1. When the changeover switch is set to the "Gas" position, the high-pressure solenoid valve should produce a crisp "click" sound. If there is no sound, it indicates that the high-pressure solenoid valve is not opened, and the natural gas circuit is blocked. You should check the voltage across the solenoid valve terminals (normal voltage should be greater than 9.6 volts) or inspect the solenoid valve coil and valve core for damage (requiring maintenance of the solenoid valve).

2. After the solenoid valve is opened, the low pressure gauge or gas volume display light should indicate the presence of air pressure, accompanied by a slight "chirp" sound indicating the flow of gas. If not, please check whether the cylinder is filled with gas or whether the natural gas shut-off valve has been opened.

3. Improper adjustment of the pressure reducer results in an excessively lean or rich mixture.

4. The excessive air intake of the air filter is caused by poor sealing or damaged air filter. It is necessary to ensure the sealing performance of the air filter.

5. If the internal pressure relief components, diaphragms, or valves of the pressure reducer are damaged, professional maintenance personnel should be called for repairs.

III. Frosting and ice blockage faults in natural gas systems

1. At low temperatures, natural gas storage and pressure relief systems may experience gas leaks or impeded gas supply due to failures such as frosting and ice blockage. It is essential to promptly check the water circulation system of the pressure reducer for smoothness. During driving, if there is a slight frosting leakage, one can use hot water with a temperature not exceeding 80 degrees Celsius to flush the frosting area, and then check whether the circulating water is unobstructed.

2. At low temperatures, natural gas pipelines may experience frosting, ice blockage, and other malfunctions during gas filling, resulting in slow filling speed or gas leakage from the gas nozzle after filling. Hot water with a temperature not exceeding 80 degrees Celsius can be used to flush away the frost. If the problem persists, professional assistance should be sought for repairs. It is strictly prohibited to start the vehicle with oil tampering and to drive without an air filter. Remember to refuel and check the cylinder valve, pipelines, and gas nozzle for leaks after parking the vehicle. When flushing the pressure reducer with hot water, the solenoid valve coil should be removed to enhance heat transfer performance and protect electrical circuits.

Refer to£ºhttps://theautojournal.com/guide/essential-tips-for-installing-a-cng-kit-in-your-car-safety-and-performance-first/

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£