How to choose a gas conversion kit for oil-to-gas?

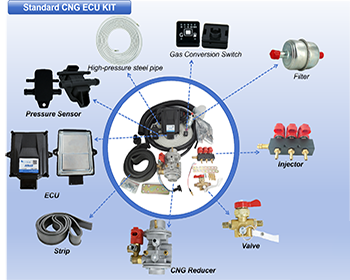

First, let's look at the core components: identify the performance of key components

The core of the gas kit consists of a pressure reducer, gas nozzle, ECU control module, gas cylinder, etc. The quality of each component directly affects the usage effect:

1. Pressure reducer (the core of the core)

- Function: Reduce the high-pressure gas (around 20MPa) in the cylinder to a low pressure (0.1-0.2MPa) suitable for engine combustion, while heating the gas (to avoid frost formation affecting gas supply).

- Selection points:

- Give priority to those with temperature control and heating functions (especially in northern regions to prevent freezing at low temperatures);

- The material should be copper or aluminum alloy forged (resistant to high pressure and corrosion, avoiding the aging and air leakage issues of cast iron parts);

- Make sure to choose the model with pressure feedback regulation (to ensure stable pressure reduction and avoid engine vibration caused by inconsistent air supply).

2. Gas nozzle (similar to fuel injection nozzle)

- Function: Precisely inject decompressed gas into the engine's intake passage to control the air supply.

- Selection points:

- The nozzle aperture needs to match the engine displacement (the larger the displacement, the larger the aperture, for example, a 2.0L model requires a larger aperture than a 1.6L model);

- Choose high-precision atomizing nozzles (the more uniform the gas atomization, the more complete the combustion, the less the power loss, and the lower the fuel (gas) consumption);

- Avoid plastic nozzles (prone to deformation at high temperatures, metal materials are preferred).

3. ECU control module ("brain")

- Function: Adjust the gas supply and ignition timing according to engine operating conditions (speed, load) to ensure compatibility with the engine (replace or assist the original fuel ECU).

- Selection points:

- Give priority to models that are adaptable and adjustable (able to automatically optimize gas supply parameters based on different road conditions and engine states, reducing the likelihood of the fault light illuminating);

- Support smooth switching between gasoline and electric power (ensuring no power interruption during switching, avoiding "jerky driving");

- Strong compatibility (especially for turbocharged models, it is necessary to choose an ECU with a "boost compensation" function to avoid insufficient air supply).

-Note: Some ECU systems now come with a fault code masking function, which is not recommended. Forcing the masking of fault codes only addresses the symptoms and not the root cause, and is not conducive to driving safety.

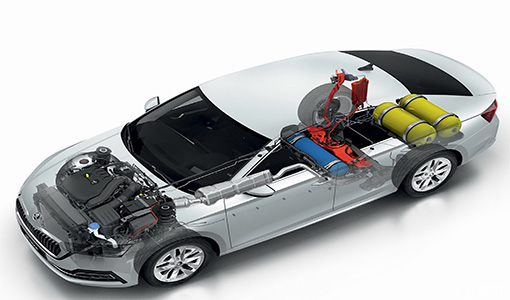

4. Gas cylinders (safety first)

- Function: Stores high-pressure gas and serves as a core safety component.

- Selection points:

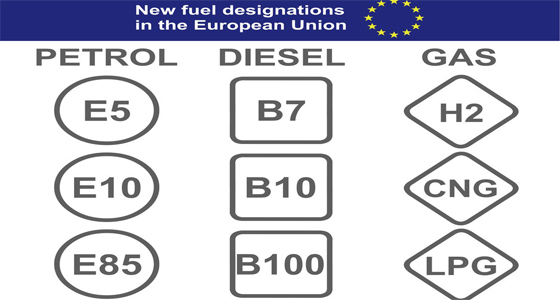

- The product must be from a nationally certified, formal manufacturer (with a "Pressure Vessel Manufacturing License", the cylinder body marked with "CNG cylinder" and regular inspection marks);

- The material is selected as the winding carbon fiber cylinder (which is more than 50% lighter than steel cylinders and has stronger impact resistance, suitable for private cars);

- Choose capacity as needed: For city commuting, choose 60-80L (with a range of 200-300 kilometers). For long-distance travel, you can choose 100-120L (but pay attention to the vehicle's load capacity to avoid overloading).

II. Identify reputable brands and qualifications: reject "unbranded, unlabeled, and unverified products"

The gas kit involves high-pressure flammable and explosive gases, and qualification and brand are the bottom line. Avoid choosing small factories or refurbished parts for the sake of cheapness:

- **Mainstream brands**: Domestic brands such as "NGV" are available; imported brands like "AC from Poland, AEB from Italy" (with good stability but higher prices);

- Beware of "assembly kits": Some small factories use inferior components for assembly without certification, and we must resolutely avoid choosing them.

III. Adaptability is key: Don't let "generic models" ruin your car

The demand for gas kits varies greatly among different vehicle models (displacement, naturally aspirated/turbocharged, fuel injection method). Blindly choosing a "universal model" can lead to a significant drop in power and frequent malfunctions:

- Naturally aspirated models: Choosing the basic package is sufficient (no need for complex tuning, high cost-effectiveness);

- Turbocharged models: It is necessary to choose a kit with "boost pressure sensing" function (additional air supply is required when the turbocharger is engaged, otherwise knock and loss of power may occur due to insufficient fuel);

- GDI (Gasoline Direct Injection) models: Choose carefully! Original direct injection engines have extremely high requirements for fuel injection accuracy, and most kits have poor adaptability, leading to carbon buildup and frequent illumination of the fault light. It is recommended to first consult with a tuning shop to see if they have successful cases.

IV. Incorporating usage scenarios: practicality is king

- Short-distance urban commuting: Prioritize the "lightweight kit" (small-capacity cylinder + simplified ECU) to reduce vehicle weight and lower modification costs;

- Long-distance high-frequency use: Choose the "Endurance Priority" package (large-capacity cylinder + high-efficiency pressure reducer), while ensuring that the ECU supports "high-speed condition optimization" (to avoid gas supply not keeping up at high speeds);

- In low-temperature regions in the north: It is necessary to choose a pressure reducer with a "low-temperature preheating" function (either built-in electric heating or heating using engine coolant) to prevent frost from blocking the pipeline during gas pressure reduction in winter.

5. Don't overlook installation and after-sales service: a good kit with poor installation is useless

- When selecting a kit, it is advisable to prioritize binding with a qualified modification factory (which must possess a "Motor Vehicle Modification Qualification" and can be registered with the local vehicle management office), to avoid the practice of "just buying the kit and installing it yourself" (improper installation is the main cause of air leaks and malfunctions);

- Ask about after-sales service: The warranty period for the kit should be at least 1 year (for core components such as pressure reducers and ECUs, a 2-year warranty is recommended), and there should be clear maintenance networks in place (to avoid the situation where the product breaks and there is no one to repair it);

- Pay attention to the annual inspection of gas cylinders: For gas cylinders with official kits, they need to be inspected once every three years for the first time. When selecting, confirm that the manufacturer can provide inspection support.

Refer to:https://www.acko.com/car-guide/cng-car-maintenance-and-safety-guide/

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£