Technical Manual for Digital Display Oil Gas Conversion Switch

1. Product Introduction

The LCD-SW oil and gas conversion switch is independently developed by NGV company and used in conjunction with a gas controller to achieve fuel switching function, gas emergency start function, gas volume display function, fault alarm function, gas leakage alarm£¨Need to be used in conjunction with a leak detector£©, digital display information on the LCD screen (speed, water temperature, switching conditions, gas cylinder volume, power mode, fault code, etc.), adaptive screen brightness function, etc It also has the following advantages:

¡¤Fast response time

¡¤The communication with the gas controller adopts pulse width modulation method, which has strong anti-interference ability;

¡¤Compatible with HN48 standard switch protocol and suitable for standard harness interfaces;

¡¤Automatic calibration function, no need for PC computer debugging, calibration work can be completed on the switch. This feature needs to be customized¡£

2. Technical parameters

2.1 Electrical Technical Parameters

|

NUM |

Category |

Parameters |

|

1 |

Operating voltage range |

5VDC (powered by gas controller) |

|

2 |

Working current |

¡Ü 20mA |

|

3 |

working temperature range |

-40 º C to+85 º C |

|

4 |

Storage temperature range |

-40 º C to+85 º C |

|

5 |

Language |

English, Chinese, Other languages can be customized |

2.2 Product Dimensions

2.3 Port Definition

3. Function Introduction

4. Installation requirements

4.1 Installation location

(1) Installed in the cockpit and convenient for the driver to operate and observe Before pasting the back adhesive of the switch, different positions should be tried to avoid the situation where the light source causes reflection on the screen and makes it inconvenient for the driver to observe;

(2) The conversion switch should be installed as far away from heat sources and strong electromagnetic radiation as possible;

(3) The wiring harness of the transfer switch should be securely fixed to prevent poor contact that may affect the display of the transfer switch panel

4.2 Precautions

(1) Avoid scaling (mud, dust, air pollution, etc.) on the surface of the switch, otherwise it will affect the panel display

(2) The conversion switch connector has an error prevention function to prevent incorrect insertion of the wiring harness;

(3) The mating end of the wire harness connector should use the wire harness connector model defined in the drawing;

(4) All mating terminals of the switch harness connector should use the wiring terminals corresponding to the harness connector model defined in the drawing If the customer chooses wiring harness connectors other than those recommended, they need to negotiate with NGV to determine;

(5) Pay attention to the power supply within the specified range to avoid damage to the internal components of the conversion switch due to overvoltage¡£

5. Fault analysis and troubleshooting

The oil gas conversion switch will clearly display the current fuel type, working status, remaining gas volume, etc. during the operation of the gas system. If there is a display error fault, the following steps can be followed to troubleshoot:

(1) Check if the wiring harness connection is normal, and re plug the wiring harness plug;

(2) Turn off the key switch, wait for the power to disconnect and then turn it back on, and observe if the fault is resolved

If the fault still cannot be resolved, please record the fault information and pass it on to NGV's after-sales service engineer

6. Other matters

6.1 Storage and transportation

During transportation, the oil and gas conversion switch should be handled with care and avoid excessive squeezing of the packaging box to prevent damage to the switch The oil and gas conversion switch should be stored in a cool, dry, and dust-free environment

6.2 Receipt and Inspection

The receiving party should check each packaging box to confirm whether the label, part number on the packaging box are consistent with the required part number for supply If any damage is found, it must be promptly reported to the relevant departments of NGV

Inspection content:

1) Check if there is any obvious physical damage to the casing of the conversion switch and if the protective film is intact;

2) Check if there is any physical damage to the connector housing and terminals of the conversion switch;

Popular articles

-

How the CNG Automotive S

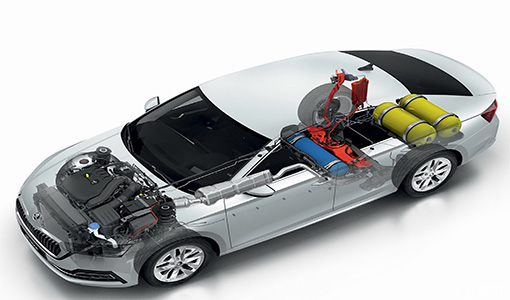

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

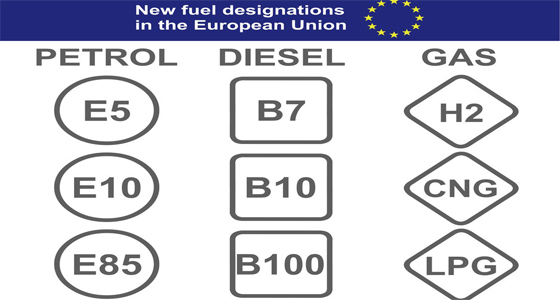

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£