Do you know about pressure reducers£¿

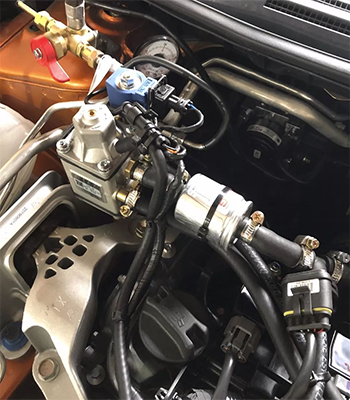

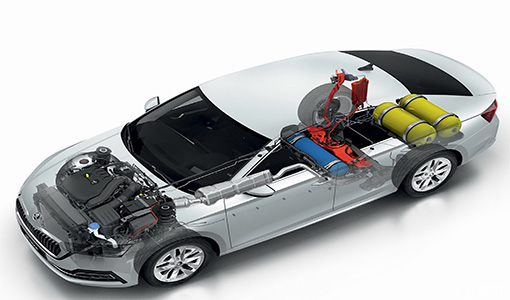

CNG pressure reducing station refers to a place where compressed natural gas (CNG) is used to provide fuel to urban gas pipelines, natural gas vehicles, and large CNG sub station vehicles. Generally, natural gas is first pre purified to remove sulfur and moisture from the gas, and then the pressure is reduced from 25MPa to 0.1MPa~1.0MPa by a regulator to achieve gas transmission function.

Three stage pressure regulation process: Firstly, high-pressure rubber hoses and quick couplings are used to connect with the pry tank truck. Compressed natural gas enters the first stage heat exchanger through high-pressure ball valves and high-pressure cut-off valves, where it is heated and then depressurized to 3.0MPa-7.5MPa through the first stage pressure regulator. It is then heated and regulated to 1.6MPa-2.5MPa through the second stage heat exchanger and pressure regulator. After three-stage pressure regulation to 0.1MPa-0.4MPa, it enters the flow meter for flow measurement, and finally odorizes the gas before entering the medium pressure pipeline network. The control of various levels of gas pressure, temperature, flow rate, water temperature, key valves, and switching between the two channels in the pressure regulating station are all interlocked and controlled by the central console.

The three-level pressure regulating station is suitable for battlefields with a flow rate of 2000Nm3/h and above. The central console is used for real-time monitoring and control of equipment operation. The pressure regulation process of compressed natural gas is much more complex compared to ordinary pipeline pressure regulation, and it is necessary to use a control panel to monitor the entire pressure regulation process.

1. The situation where emphasis is placed on both power performance and gas consumption.

2. Have a testing report from a national professional testing institution.

3. Price of pressure reducers and our company's reputation and after-sales service system.

4. Technical data and maintainability of the pressure reducer.

5. Choose an engine model that is suitable for natural gas modification in automobiles, and it is best to have supporting tests to prove it.

6. Adapt to the intended use of oil to gas vehicles and the main operating conditions of the engine.

7. Choose to adapt to the local climate conditions. 8. The lifespan of the pressure reducer and the quality of its components.

Refer to£ºhttps://en.wikipedia.org/wiki/Pressure_regulator

Refer to£ºhttps://en.wikipedia.org/wiki/Pressure_regulator

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them

Popular articles

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£