Working Principle of Gas Injection Rail

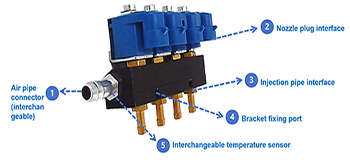

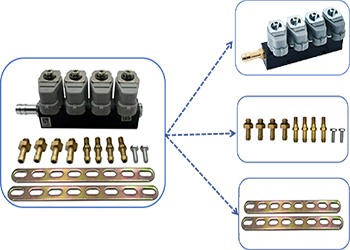

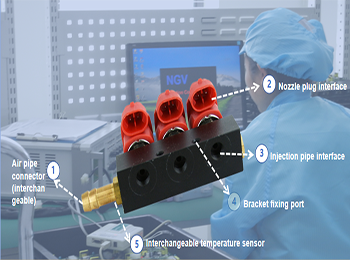

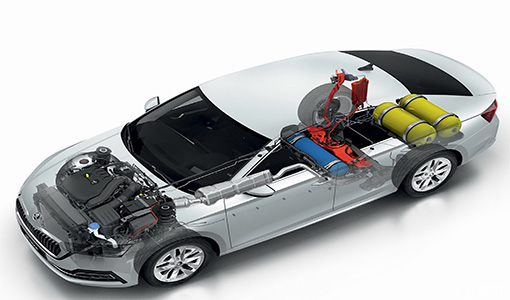

1. Gas is stored in the guide rail and sprayed into the engine intake pipe through a nozzle.

2. Computer controlled nozzle spraying. Install 3 or 4 nozzles on the guide rail to adapt to different vehicle models.

3. The temperature and pressure of the gas entering the guide rail can be monitored, with a maximum operating pressure of 300Kpa. The high-frequency electromagnetic valve operates 7500 times per minute.

4. When the electromagnetic coil of the spray rail is energized, suction is generated, and the needle valve is sucked up, opening the spray hole. Gas is sprayed out at high speed through the annular gap between the shaft needle of the needle valve head and the spray hole, forming a mist, which is conducive to full combustion. Its main function is to inject fuel from the pressure reducer into each cylinder.

1. When the air pressure is insufficient, it is possible that the speed cannot be increased or the vehicle may experience acceleration.

2. When the air pressure is unstable, the reaction will be slow and impulsive.

3. Excessive air pressure can cause engine shaking, incomplete combustion, and poor fuel economy, as well as environmental pollution.

1. It is recommended to clean the gas spray rail every 10000 kilometers. If the gas spray rail is not working properly or malfunctions, it should be replaced.

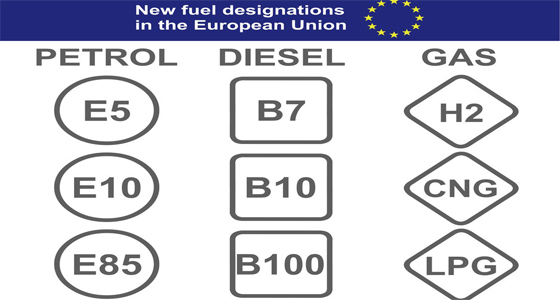

2. Gas injection rails are essential for gas burning cars, as they supply air to the engine.

3. The common gasoline engines are electronic fuel injection engines, which rely on electronic fuel injection mechanisms to supply fuel to the engine. There are three injection methods for electronic fuel injection engines, namely multi-point injection, cylinder direct injection, and hybrid injection. The earliest single point injection has been phased out.

4. Many car engines are using turbocharged direct injection technology, which directly places the fuel injector in the cylinder. The advantage of this is that it can mix gasoline and air more thoroughly, and the injection pressure of gasoline is higher, resulting in more thorough gasoline atomization.

5. Generally, engines equipped with in cylinder direct injection technology have higher horsepower than multi-point electronic injection engines.

Hybrid injection refers to both direct and multi-point injection in the cylinder, and using different injection methods under different operating conditions is beneficial for improving engine efficiency and reducing emissions. Direct injection engines in the cylinder are prone to carbon deposits, and it is recommended that car enthusiasts who use direct injection engines in the cylinder clean up the carbon deposits at regular intervals.

Refer to£ºhttps://alexlpg.com/en/how-do-lpg-injectors-work-and-what-is-their-role/

Refer to£ºhttps://alexlpg.com/en/how-do-lpg-injectors-work-and-what-is-their-role/

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Working Principle Of CNG

Working principle of gas injection rail

-

How To Improve The Power

1. Install ignition advance angle What i

Latest comments

0piece comment

no comments, welcome to comment¡£